Technical Integration of Surfacing Processes and Chrome Carbide Wear-Resistant Plates

Release Time:

14 Apr,2025

Author:

Source:

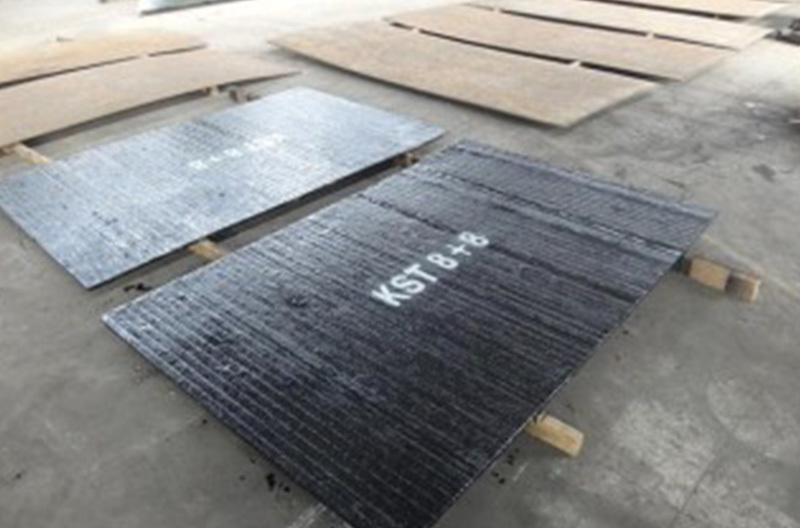

Chrome carbide wear-resistant overlay plates feature a composite structure of "tough steel matrix + high-hardness chromium carbide layer...

I. Core Value of Surfacing Processes in Chrome Carbide Plate Manufacturing

II. Oxygen-Acetylene Surfacing Welding for Chrome Carbide Plates

1. Process Adaptation in Chrome Carbide Plate Production

- Target applications: Small-batch chrome carbide overlay wear plates for valves, drill bits, and plowshares, where surface smoothness and precision matter. For instance, chrome carbide overlay parts like crusher liners benefit from this process’s thin, uniform cladding (≤1.6 mm).

- Cost consideration: Using scrap chrome carbide alloys reduces chrome carbide plate price, making it viable for low-volume custom orders.

2. Technical Advantages for Chrome Carbide Wear Resistance

- Dilution control: Maintaining <0.1 mm molten depth preserves the chromium carbide layer’s hardness (HRC 55-65), critical for AR600 and wear resistant 450 plate equivalents.

- Flame optimization for chrome carbide:

- High-chromium cast iron layers use 3x excess acetylene flame to promote Cr7C3 formation, enhancing wear resistance comparable to tungsten carbide in impact-heavy scenarios.

III. Oxygen-Acetylene Spray Welding for Chrome Carbide Overlay Plates

1. Spray Melting for High-Performance Chrome Carbide Layers

- Self-fluxing powders: Ni-B-Si alloys sprayed onto chrome carbide overlay wear plates create dense, pore-free layers (HRC 60-65), outperforming arc-welded surfaces in abrasion tests.

- Two-step process for thick plates: Ideal for fabricating chrome carbide plate with 0.5-3 mm cladding, reducing defects in multi-layer builds for mining conveyor components.

2. Bond Strength and Application Notes

- Compared to tungsten carbide, chrome carbide overlay plates offer 300+ MPa bond strength at lower cost, suitable for excavator bucket teeth and other chrome carbide overlay parts.

IV. Arc Welding in Chrome Carbide Plate Production

1. On-Site Repair and Batch Manufacturing

- Cost-effective solutions: Arc welding lowers chrome carbide plate price for large-scale production, such as mine truck floors and screw conveyor blades.

- Multi-layer considerations: Using D688 electrodes on chrome carbide wear resistant 450 AR600 plate reduces dilution, though preheating (150-250°C) is vital to prevent cracking in high-carbon substrates.

2. Electrode Selection for Chrome Carbide Cladding

- Titanium calcium electrodes (DC reverse) ensure HRC 50-55 hardness in iron-based chrome carbide layers, while graphite electrodes promote carbide formation in high-chromium deposits.

V. Chrome Carbide Plate Price Factors and Market Trends

- Price drivers: Thickness (1-10 mm), alloy composition (nickel vs iron-based), and production scale influence chrome carbide plate price, typically ranging from $50-$200 per sq.ft.