Products

Contact Us

Wear Resistant Steel

Hard 400 450 550 500 600 Wear Resistant Steel From Swedish Steel Plate

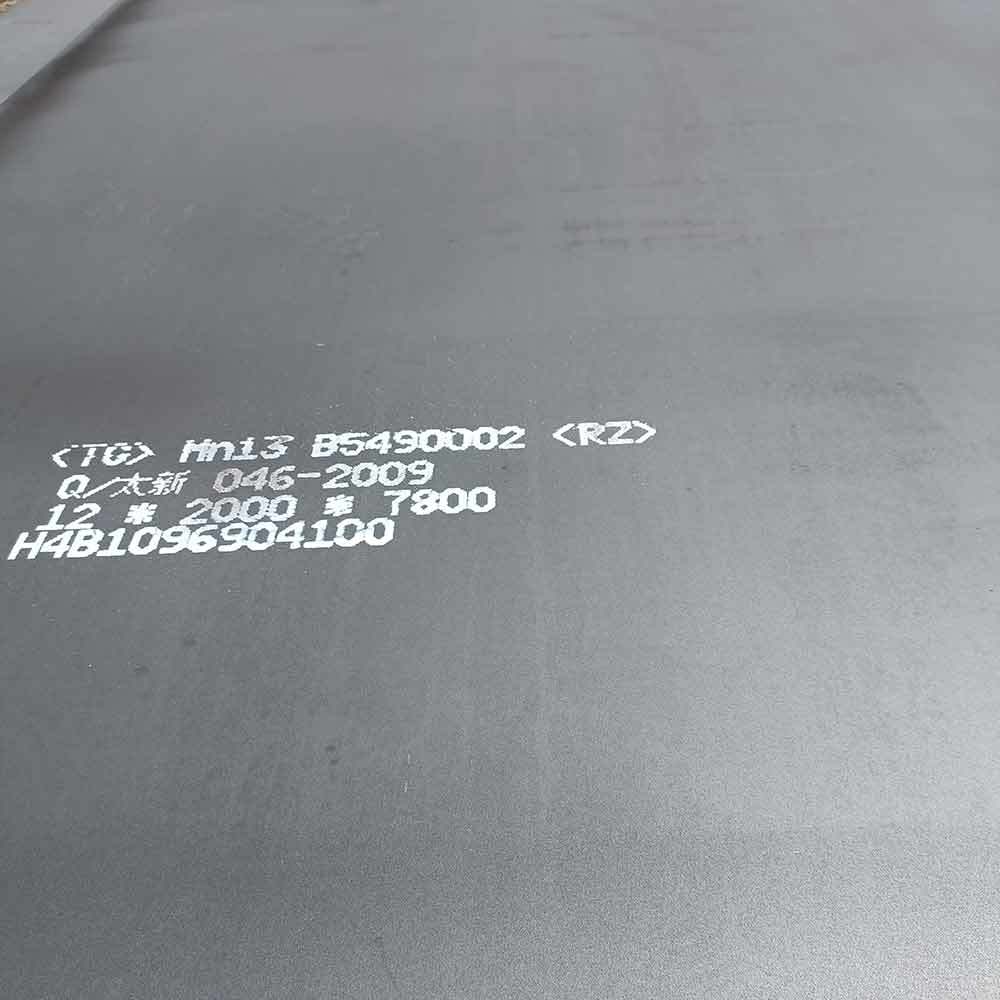

High Manganese Steel Plate ASTM A128 Mn13 X120Mn12 SCMNH11 Wear Resistant Factory Price

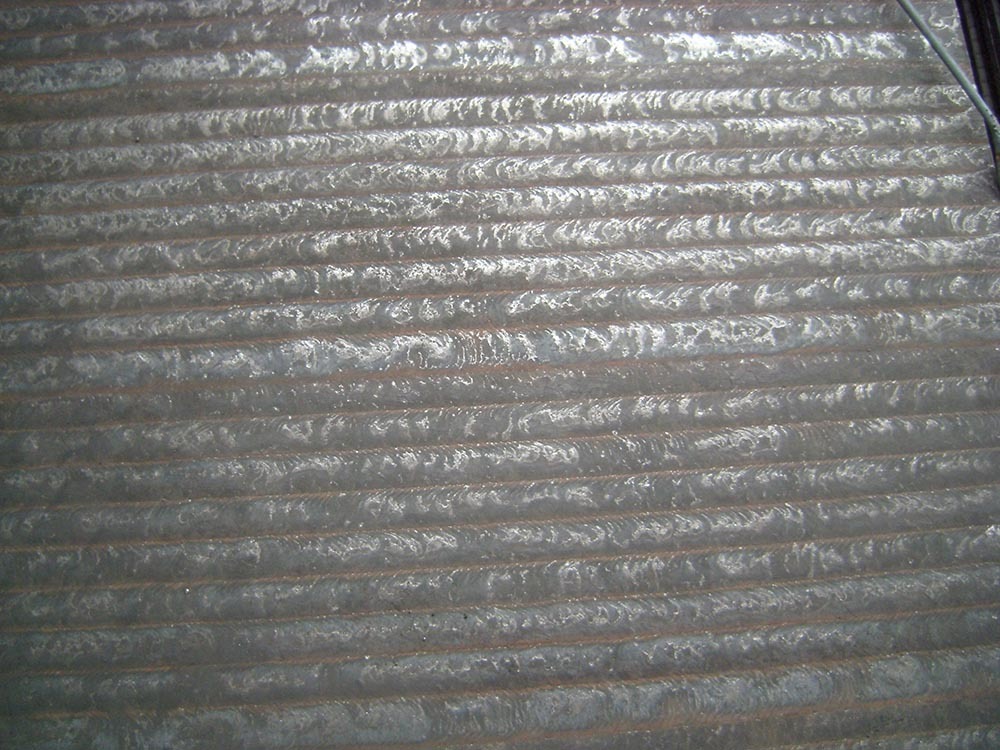

Chrome Carbide Overlay Wear Plate

Teda Ganghua Metal Steel offers customized chromium carbide overlay plates, engineered for extreme wear, impact, and heat resistance. These abrasion-resistant steel plates feature a fusion-bonded chromium carbide layer applied to a mild steel base using advanced surfacing and submerged arc welding technology.

Wear Resistant Steels Manufacturers

Wear Resistant Steel Properties

Wear Resistant Steel Plate Market

Wear Resistant Stainless Steel Grades

Best Steel For Wear Resistance