Products

Contact Us

Cold rolled 321 stainless steel plate with 2b/Hl/No. 4/8K Mirror Finish

Category:

Product Details

Cold rolled 321 stainless steel plate

In metallurgy, stainless steel plate, also known as Inox steel or Inox from French Inoxydable

(inoxidizable), is a steel alloy with a minimum of 10.5% chromium content by mass;Stainless steels are notable for their corrosion resistance, which increases with increasing chromium content. Additions of molybdenum increase corrosion resistance in reducing acids and against pitting attack in chloride solutions; Thus, there are numerous grades of stainless steel with varying chromium and molybdenum contents to suit the environment the alloy must endure. Please click on www.teda-metal.com more products about stainless steel

Understanding 321 Stainless Steel:

321 stainless steel is a stabilized austenitic stainless steel alloy, designed to provide improved resistance to intergranular corrosion and oxidation in high-temperature environments. The stabilization is achieved through the addition of titanium, which forms carbides that inhibit chromium carbide precipitation at grain boundaries during exposure to elevated temperatures. This ensures the retention of corrosion resistance and mechanical properties, even in challenging conditions.

There are four main families, which are primarily classified by their crystalline structure:

Austenitic stainless steel

200 Series: 201, 202

300 Series: 304, 304L, 309S, 310S, 316, 316L, 316Ti, 317L, 321, 347

Ferritic stainless steels

409L, 430, 436, 439, 441, 444, 446

Martensitic stainless steels

410, 410S, 416, 420J1, 420J2, 431、440,17-4PH

Duplex and Special Stainless: S31803, S32205, S32750, 630, 904L

Thickness

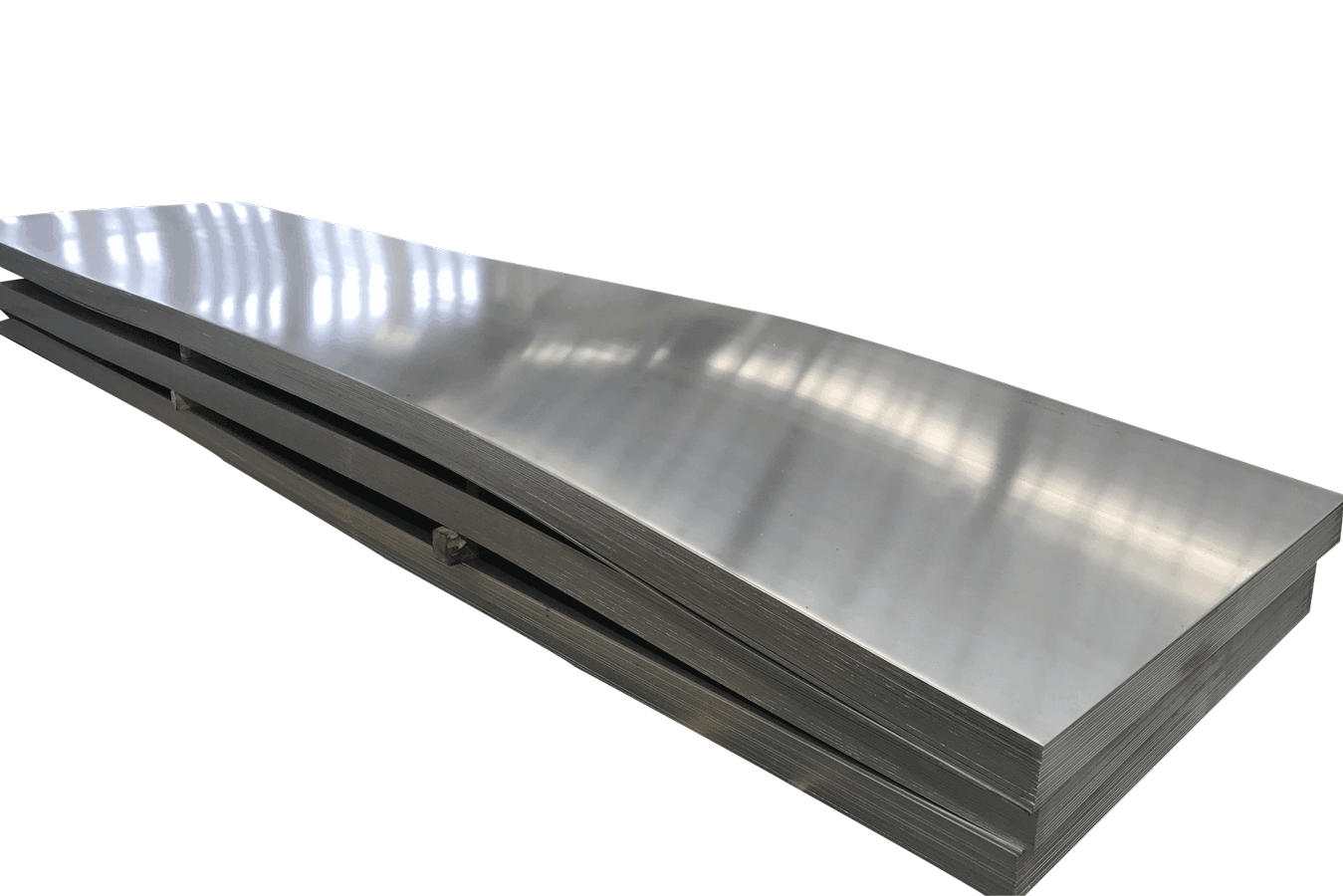

0.4- 6mm for 2B cold rolled sheet/coil ;

3.0-16mm for No.1 hot rolled coils;

3.0-100mm for No.1 hot rolled plate ;

Width

1000/1219/1500mm for cold rolled ; 1500/1800/2000mm for hot rolled;

Length

Standard length 2000/2438/3000/6000mm or as required;

Strips: width less than 600mm, and common for 2B cold rolled thickness;

Cold rolled 321 stainless steel plate

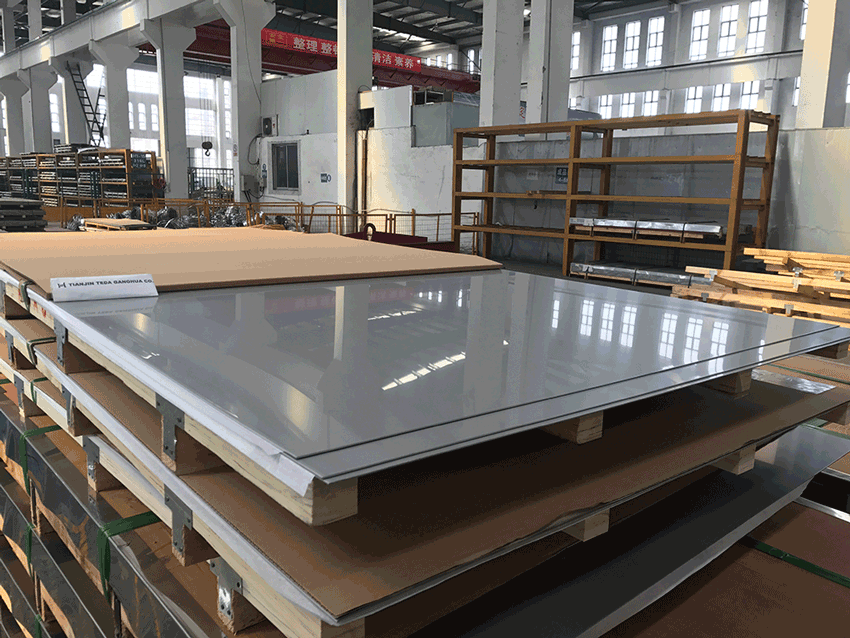

Mill Finish: 2B for cold rolled; No.1 for hot rolled;

Processing Finish:No.4, HL, BA, Mirror, Etched, Bead blast, Vibration etc.;

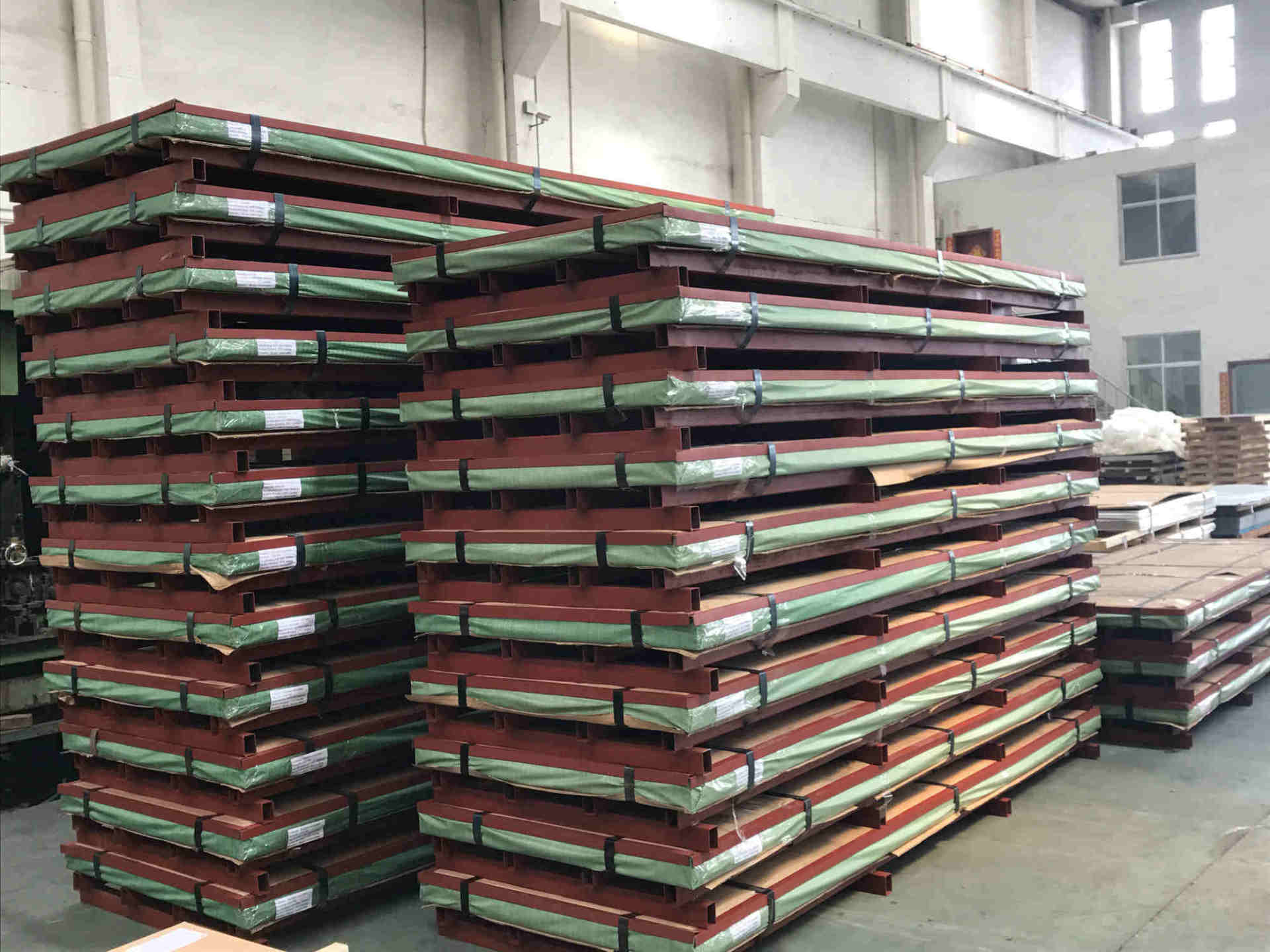

Standard export package with metal pallet or as requirement;

TISCO, BAOSTEEL, LISCO, JISCO, POSCO

Stainless steel's resistance to corrosion and staining, low maintenance, and familiar lustre make it an ideal material for many applications where both the strength of steel and corrosion resistance are required, as Architecture, Bridges, Art, Monuments and Sculptures, Cookware, Railway vehicle parts etc.

Composition:

The composition of 321 stainless steel typically includes iron as the primary element, along with chromium, nickel, and a stabilizing addition of titanium.

Manganese, silicon, and small amounts of other alloying elements may also be present to enhance specific properties. The key components are:

Chromium (17-19%): Provides excellent corrosion resistance, particularly against oxidizing environments.

Nickel (9-12%): Enhances ductility, toughness, and resistance to corrosion and oxidation.

Titanium (5 times carbon content): Stabilizes the alloy and prevents chromium carbide precipitation, ensuring intergranular corrosion resistance.

Characteristics:

321 stainless steel boasts a range of remarkable characteristics that make it a preferred choice in various applications:

Corrosion Resistance: Offers excellent resistance to corrosion in both oxidizing and reducing environments, including intergranular corrosion.

High Temperature Stability: Maintains its mechanical properties and corrosion resistance at elevated temperatures, making it suitable for high-temperature applications.

Weldability: Exhibits good weldability and formability, allowing for ease of fabrication and construction.

Creep and Stress Rupture Strength: Possesses good creep and stress rupture strength, ensuring reliability in demanding environments.

Excellent Toughness and Ductility: Provides a combination of toughness, ductility, and strength, contributing to its suitability for a wide range of applications.

Applications:

321 stainless steel finds extensive use across various industries and applications, including but not limited to:

Aerospace: Used in aircraft components, exhaust systems, engine parts, and heat exchangers due to its high temperature stability and corrosion resistance.

Chemical Processing: Employed in chemical processing equipment, reactors, and piping systems exposed to corrosive chemicals and high temperatures.

Automotive: Utilized in automotive exhaust systems, mufflers, and catalytic converters for its resistance to oxidation and thermal cycling.

Food and Beverage: Found in food processing equipment, storage tanks, and piping systems due to its corrosion resistance and hygienic properties.

Heat Exchangers: Used in heat exchangers and boilers for its ability to withstand high temperatures and corrosive environments.

Conclusion:

321 stainless steel stands as a testament to the remarkable advancements in materials science, offering a unique combination of corrosion resistance, high temperature stability, and weldability. From aerospace to chemical processing, automotive, and beyond, 321 stainless steel continues to play a pivotal role in enabling technological advancements and driving innovation. As industries evolve and demand for high-performance materials grows, the enduring appeal of 321 stainless steel as a reliable and versatile alloy is unlikely to diminish, solidifying its status as a cornerstone material in modern engineering and manufacturing.

Cold rolled 321 stainless steel plate

Our cold-rolled stainless steel sheets range in thickness from 0.4 to 8.00 mm, while our hot-rolled sheets range from 3.00 mm to 200 mm.

Standard stainless steel sheet dimensions are: 1000×2000 mm; 1250×2500 mm and 1500×3000 mm. We can supply custom sheet sizes under separate orders.

Product Inquiry

Relevant Products