Products

Contact Us

316 Stainless Steel Bar Stock

Keywords:

Category:

Product Details

316 stainless steel rods, available in flat, round, and square profiles, is a premium-grade stainless steel metal bar ideal for high-performance use across marine, petroleum, food processing, aerospace, and chemical industries. Known for its exceptional corrosion resistance—especially in chloride-rich and marine environments—316 stainless is a top-tier option among the 300 stainless steel bar series.

As a trusted stainless steel bar supplier, we offer a full range of 316 stainless steel bar stock, including custom-cut sizes and competitive pricing across various dimensions.

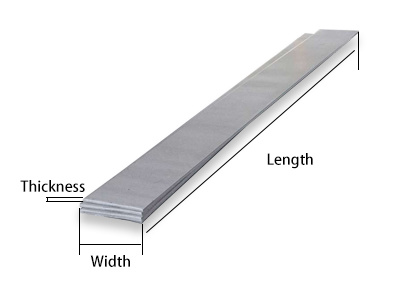

316 Stainless Steel Flat Bar

316 Stainless Steel Flat Bar

316 stainless steel flat bar is an austenitic chromium-nickel alloy enhanced with molybdenum, delivering superior resistance to pitting and crevice corrosion. Stronger than 304 but slightly less machinable, this flat bar is commonly used in:

-

Marine-grade stainless steel structures

-

Architectural supports and railing systems

-

Food-grade and chemical processing equipment

Benefits:

-

Excellent performance in high-heat and cryogenic conditions

-

Superior to 304 in saltwater resistance

-

Available in standard and custom-cut sizes

Looking for a more general-purpose option? We also stock 303 stainless steel bar, known for its excellent machinability, and 410 stainless steel bar, preferred for high-strength, heat-treated applications.

316 Stainless Steel Round Bar (Rod)

316 Stainless Steel Round Bar (Rod)

We carry a wide range of 316 stainless steel round bar sizes—from stainless steel rods 3mm to large-diameter stock, including 1/2 round stainless steel bar and 4mm stainless steel round bar. Also referred to as 316 stainless rod, it is widely used in:

-

Precision machining

-

Load-bearing structural components

-

Wet and corrosive environments

Key Properties:

-

Tensile Strength: 75 ksi

-

Yield Strength: 30 ksi

-

Elongation: 60%

-

Brinell Hardness: 160

-

Density: 0.289 lb/in³

-

Melting Point: 2500–2550°F

As an indispensable material in modern industry, stainless steel bar offers numerous reliable advantages. First, it's highly corrosion-resistant, maintaining stable performance even in the presence of humid air and chemical media, making it particularly suitable for outdoor use or in harsh environments. Second, stainless steel round bar boasts exceptional strength and toughness, offering excellent resistance to pressure and impact. Even under long-term loads, it resists deformation and ensures structural stability and safety.

In terms of processing, stainless steel round bar offers excellent machinability and weldability, facilitating various processes such as turning, milling, and drilling, adapting to various industrial manufacturing needs. Its high surface finish and aesthetic appeal make it suitable for decorative structural parts requiring a high level of aesthetic appeal. Furthermore, its long service life reduces maintenance and replacement frequency, resulting in greater long-term economic benefits.

With its multiple advantages of durability, corrosion resistance, ease of processing, and attractive appearance, it is an ideal choice for industries such as construction machinery, building structures, automotive manufacturing, marine components, and home hardware. Choosing it means choosing a stable and reliable solution.

1. Corrosion resistance.

2. High temperature oxidation resistance.

3. Physical properties.

316 vs 316L Stainless Steel Bar

316L stainless steel round bar is a low-carbon variation of 316 that offers improved weldability and resistance to carbide precipitation during welding. It is ideal for heavy gauge components like tanks, pressure vessels, and piping systems in corrosive environments.

Dual-certified 316/316L bars are commonly used in:

-

Marine hardware

-

Pulp and paper manufacturing

-

Industrial filtration systems

📌 Note: The price difference between 316 and 316L stainless steel is minimal, making 316L a cost-effective solution for weld-intensive applications.

Teda Ganghua Metal

Teda Ganghua Metal is an 18 year old stainless steel stockist and supplier with a large warehouse and own processing plant in China. We are metal experts and have been providing excellent customer service and products since 2006.

Teda Ganghua Metal supplies stainless steel for a variety of applications. Our stock includes: stainless steel coils in various grades as well as stainless steel sheets.

316L stainless steel bar: 316 stainless steel contains molybdenum and low carbon content. It has better resistance to pitting corrosion in marine and chemical industrial environments than 304 stainless steel! (316L low carbon, 316N high nitrogen, high strength, 316F stainless steel with high sulfur content, easy to cut stainless steel.

304L stainless steel bar: As a low carbon 304 steel, in general, the corrosion resistance is similar to that of 304, but after welding or after stress relief, its resistance to intergranular corrosion is excellent, and it can also be used without heat treatment. Maintain good corrosion resistance.

304 stainless steel bar: It has good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, and no heat treatment hardening. Uses: tableware, cabinets, boilers, auto parts, medical equipment, building materials, food industry (use temperature -196 ° C -700 ° C).

310 stainless steel bar: The main features are: high temperature resistance, generally used in the boiler, car exhaust pipe. Other properties in general.

303 stainless steel bar: It is easier to cut than 304 by adding a small amount of sulfur and phosphorus. Other properties are similar to those of 304.

302 stainless steel rod: 302 stainless steel rod is widely used in auto parts, aviation, aerospace hardware tools, chemical industry. The details are as follows: crafts, bearings, sliding flowers, medical equipment, electrical appliances, etc. Characteristics: 302 stainless steel ball belongs to austenitic steel, which is close to 304, but the hardness of 302 is higher, HRC ≤ 28, with good rust and corrosion resistance.

301 stainless steel bar: good ductility for molding products. It can also be hardened by mechanical processing. Good weldability. Wear resistance and fatigue strength are better than 304 stainless steel.

202 stainless steel bar: belongs to chrome-nickel-manganese austenitic stainless steel, the performance is better than 201 stainless steel.

201 stainless steel bar: belongs to chrome-nickel-manganese austenitic stainless steel, low magnetic.

410 stainless steel bar: Martensitic (high-strength chrome steel), good wear resistance and poor corrosion resistance.

420 stainless steel bar: "cutting grade" martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. Also used for surgical knives, it can be done very brightly.

430 stainless steel bar: ferritic stainless steel, for decoration, for example for car accessories. Good formability, but poor temperature and corrosion resistance.

metal rods stainless steel rod

●Construction field, ships building industry

●Petroleum & chemical industries, war and electricity industries

●Food processing and medical industry

●Boiler heat exchanger, machinery and hardware fields

Product Inquiry

Relevant Products