Products

Contact Us

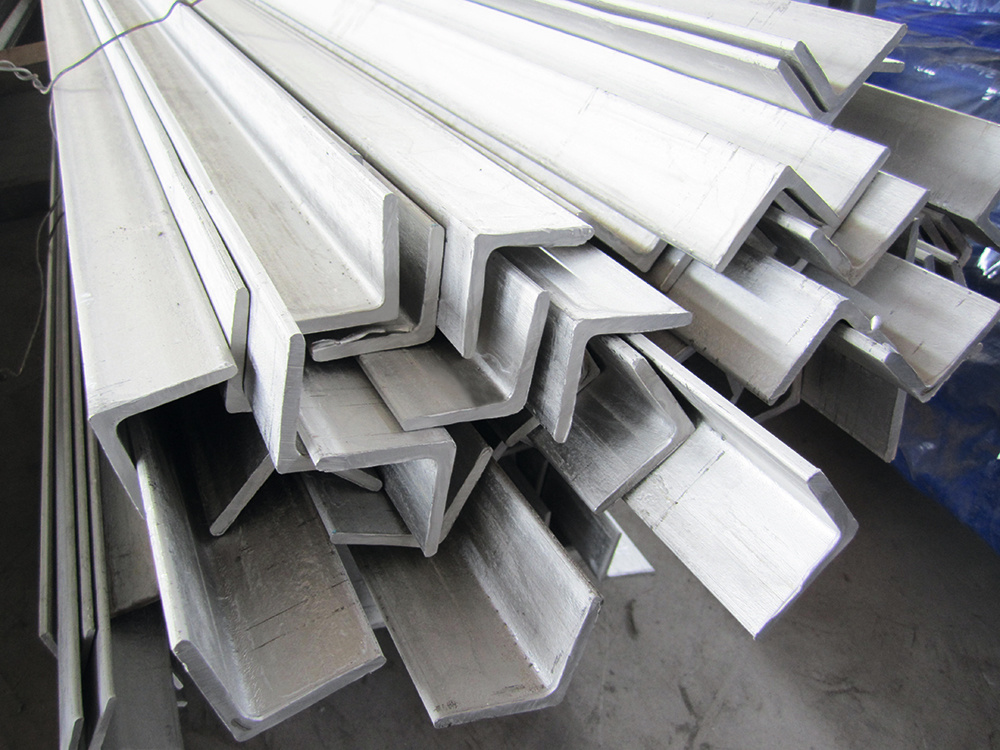

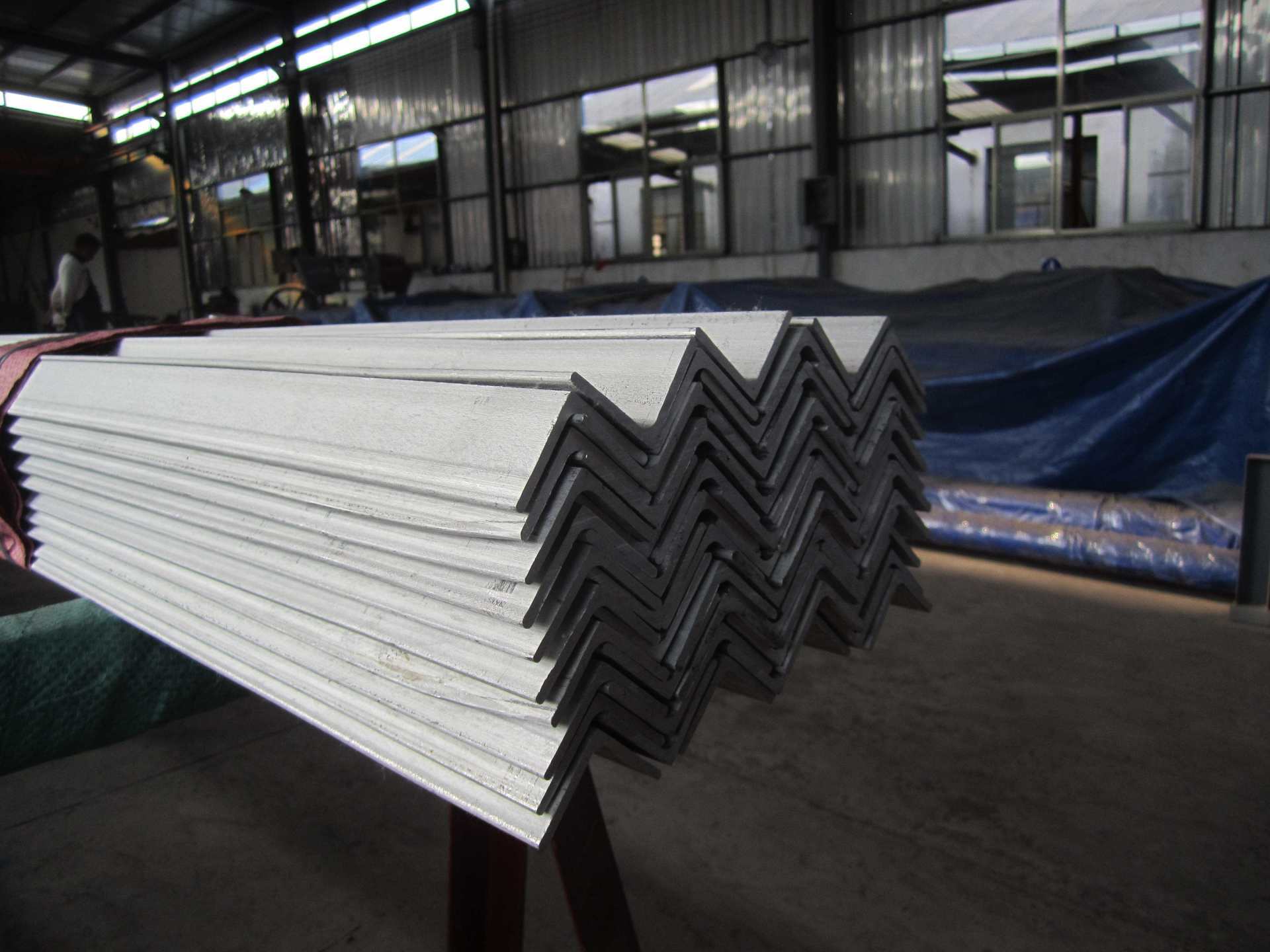

stainless steel angle bar 316

Category:

Product Details

Process Description

The surface treatment process of iron angle rods and stainless steel bars is the key link to improving their performance and aesthetics. Common treatment methods include pickling passivation, polishing, electroplating, electrolytic polishing, and sandblasting etc. Each process has its unique advantages.

Pickling passivation is mainly used to remove surface oxide scale and impurities, enhance corrosion resistance, and is particularly suitable for stainless steel materials after welding or heat treatment. Polishing is divided into mechanical polishing and chemical polishing, which can make the surface smooth and delicate, enhance the overall visual effect, reduce dirt adhesion, and improve cleanliness.

Electrolytic polishing further refines the surface through electrochemical reaction, which can significantly improve brightness and corrosion resistance, and is often used in application scenarios with high surface requirements. Electroplating can cover a layer of metal layer such as nickel or chromium, on the surface to enhance hardness, wear resistance, and decorative effect. Sandblasting can achieve a matte or uniform roughness effect, improve coating adhesion, and is often used for subsequent pre-spraying treatment.

By reasonably selecting and combining different surface treatment methods, iron angle rod and stainless steel bar can achieve dual improvement of function and appearance according to application requirements, meeting the technical standards and aesthetic needs of different industries.

|

Grade |

SS201, 202, 304/304L, 316L, 309S, 310S, 316Ti, 317L, 321, 419L, 410S, 430,420J1, 439, 441, 444, S32205, S31803, S32750, 904L; |

|

Type |

Equal and Unequal |

|

Surface |

2B finish, Pickled finish,B lack finish ,Mirror finish, Brushed finish |

|

Condition |

Cold Drawn, Hot Rolled & Pickled, Hot Rolled Black Bar |

|

Thickness |

Cold Drawn 0.3-3.0mm, Hot Rolled 3.0-24mm |

|

width |

25-200mm |

|

Length |

3000mm, 5800mm, 6000mm, or as required |

|

Package |

Waterproof paper + Nylon bag, Plastic strip, or according to the customer's request |

iron angle bar stainless steel

|

Product name |

stainless steel round bar and square bar |

|||

|

Grade |

200,300,400series, 201,202,301,304,309S,310S,316,316L,410,420,430,etc. |

|||

|

Technology |

Bright, Polished, Turn smooth(Peeled),Brush, Mill, Pickled etc |

|||

|

Type |

Round,square,hexagonal,flat,angle |

|||

|

Specification |

Round bar |

Diameter: 3mm~800mm |

||

|

Angle bar |

Size: 3mm*20mm*20mm~12mm*100mm*100mm |

|||

|

Square bar |

Size: 4mm*4mm~100mm*100mm |

|||

|

Flat bar |

Thickness: 2mm~100mm Width: 10mm~500mm |

|||

|

Hexagonal |

Size: 2mm~100mm |

|||

|

Standard |

ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,GB/T 1 |

|||

Common Specification (mm)

iron angle bar stainless steel

|

25*25*3 |

30*30*3 |

40*40*4 |

50*50*5 |

60*60*6 |

|

70*70*5 |

75*75*5 |

80*80*10 |

90*90*8 |

90*90*12 |

|

100*100*6 |

100*100*10 |

110*110*12 |

125*125*10 |

125*125*14 |

|

140*140*12 |

160*160*14 |

180*180*16 |

200*200*14 |

200*200*20 |

|

25*16*3 |

32*20*4 |

40*25*4 |

50*32*4 |

63*40*5 |

|

70*45*5 |

85*50*5 |

90*50*5 |

100*80*8 |

110*70*10 |

|

125*80*10 |

140*90*14 |

160*100*16 |

180*110*16 |

200*125*14 |

Weather Resistance

Stainless steel bars can maintain structural stability and a smooth surface for a long time in different climate environments. It has strong corrosion resistance and can effectively resist the erosion of metal by rain, moisture, salt spray, etc. It is suitable for harsh environments such as seaside, chemical industry, and outdoor facilities. Even if it is exposed to sunlight and wind, and rain for a long time, it is not easy to rust and deform. Its service life is significantly better than that of ordinary steel, making it an ideal choice for reliability and durability in engineering construction.

Product Inquiry

Relevant Products