Products

Contact Us

Forming stainless steel sheet

Category:

Product Details

PRODUCT DESCRIPTION

Forming stainless steel sheet is a process that shapes flat stainless steel sheet into specific geometric shapes through various metal processing methods. Its core function is to make the hard stainless steel material have the three-dimensional structure required by the design while maintaining the original strength and corrosion resistance through processes such as bending, stretching, and stamping. This processing method not only improves the utilization rate of materials, but also makes the manufacturing of complex parts more efficient and controllable.

The formed stainless steel sheet has good structural integrity and beautiful appearance, which can meet the manufacturing needs with strict requirements on precision, durability, and functionality. Its unique processing performance makes the design more flexible, whether it is a shallow drawn structure or a multi-bent edge, it can be precisely controlled. Since stainless steel itself has excellent anti-rust and anti-corrosion properties, the formed sheet can still maintain stable quality and finish in harsh environments.

In metallurgy, stainless steel plate, also known as Inox steel or Inox from French Inoxydable (inoxidizable), is a steel alloy with a minimum of 10.5% chromium content by mass. Stainless steels are notable for their corrosion resistance, which increases with increasing chromium content. Additions of molybdenum increase corrosion resistance in reducing acids and against pitting attack in chloride solutions. Thus, there are numerous grades of stainless steel with varying chromium and molybdenum contents to suit the environment the alloy must endure.

Stainless Steel Families

There are four main families, which are primarily classified by their crystalline structure:

Austenitic stainless steel

200 Series: 201, 202

300 Series: 304, 304L, 309S, 310S, 316, 316L, 316Ti, 317L, 321, 347

Ferritic stainless steels

409L, 430, 436, 439, 441, 444, 446

Martensitic stainless steels

410, 410S, 416, 420J1, 420J2, 431、440,17-4PH

Duplex and Special Stainless: S31803, S32205, S32750, 630, 904L

SPECIFICATION

Thickness

0.4- 6mm for 2B cold rolled sheet/coil ;

3.0-16mm for No.1 hot rolled coils;

3.0-100mm for No.1 hot rolled plate ;

Size

Any size you need based on drawings

Surface Finish

Mill Finish: 2B for cold rolled; No.1 for hot rolled;

Processing Finish:No.4, HL, BA, Mirror, based on requirement;

Package

Standard export package with metal pallet or as requirement;

Brand

TISCO, BAOSTEEL, LISCO, JISCO, POSCO

Application

The stainless steel forming sheet processing service provided by TEDA GANGHUA relies on advanced equipment and rich technical accumulation to provide customers with customized solutions. From the selection of raw materials to the design of the forming process, every detail is strictly controlled to ensure that the finished product achieves ideal results in terms of dimensional accuracy, surface treatment, and structural strength. Whether you need stainless steel components for industrial manufacturing or pursue high-end appearance, we can provide you with one-stop service from design concept to finished product delivery, helping your project to be more efficient and professional.

Stainless steel's resistance to corrosion and staining, low maintenance, and familiar lustre make it an ideal material for many applications where both the strength of steel and corrosion resistance are required, as Architecture, Bridges, Art, Monuments and Sculptures, Cookware, Railway vehicle parts etc.

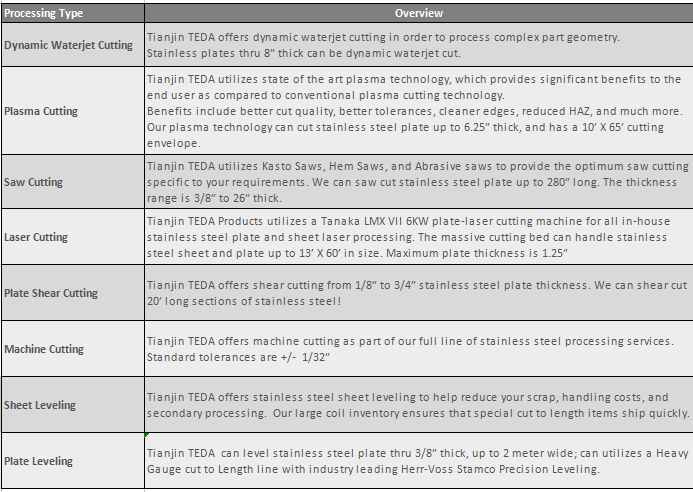

Processing

Custom stainless & sheet metal

Product Inquiry

Relevant Products