Products

Contact Us

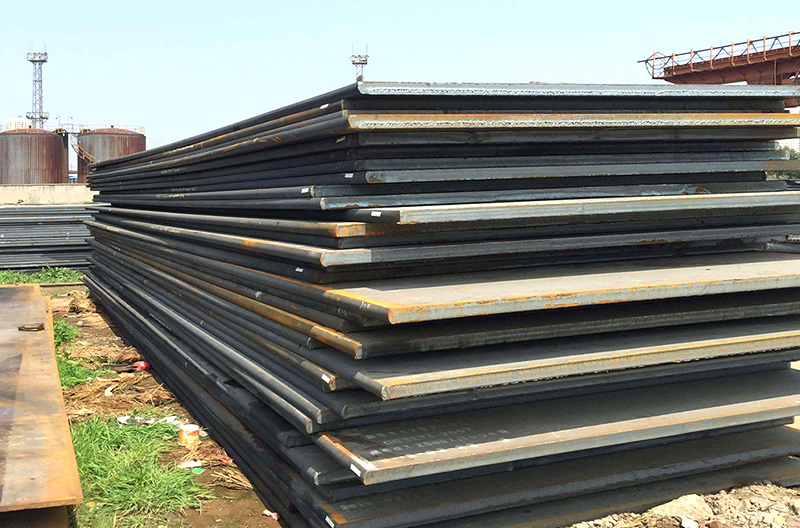

High Quality AR400/450/500 Low Carbon Steel Sheet Coil

Category:

Product Details

Advantages and Value

Under high-intensity working conditions, Wear resistant steel plate provides economical and efficient solutions for various industrial users with their excellent wear resistance and excellent structural strength. Compared with ordinary structural steel, wear-resistant steel greatly improves the surface hardness and impact resistance by adding elements such as chromium and manganese to the alloy ratio and undergoing a special heat treatment process. Its outstanding advantages are: significantly extending the service life, reducing the frequency of replacement, and reducing the cost of downtime and maintenance, thereby helping customers achieve lower total operating costs (TCO) and higher equipment availability. For users who pursue efficient operations, wear-resistant steel is not only a material, but also a value investment.

Specification

Grade: NM360, NM400, NM450, NM500, NM550, NM600

SSAB grade: Hardox 400, Hardox 450, Hardox 500

Thickness: 3-80mm

Width: 1250mm, 1500mm, 1800mm, 2000mm, 2200mm

Length: 6000mm, 8000mm, 10000mm, or cut to required.

Chemical Composition,/% | |||||||||||

Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | B | AlS |

≤ | Range | ≥ | |||||||||

NM360 | 0.25 | 0.70 | 1.60 | 0.025 | 0.015 | 0.80 | 0.50 | 0.50 | 0.05 | 0.0005-0.006 | 0.01 |

NM400 | 0.30 | 0.70 | 1.60 | 0.025 | 0.010 | 1.00 | 0.70 | 0.50 | 0.05 | 0.0005-0.006 | 0.01 |

NM450 | 0.35 | 0.70 | 1.70 | 0.025 | 0.010 | 1.10 | 0.80 | 0.55 | 0.05 | 0.0005-0.006 | 0.01 |

NM500 | 0.38 | 0.70 | 1.70 | 0.02 | 0.010 | 1.20 | 1.00 | 0.65 | 0.05 | 0.0005-0.006 | 0.01 |

Mechanical Properties | |||||

Grade | Thickness/mm | Rm/Mpa | A50/% | -20℃KV2/Jitudinal) | HBW |

NM360 | ≤80 | ≥1100 | ≥12 | ≥24 | 330-390 |

NM400 | ≤80 | ≥1200 | ≥10 | ≥24 | 370-430 |

NM450 | ≤80 | ≥1250 | ≥7 | ≥24 | 420-480 |

NM500 | ≤70 | ≥1300 | ≥7 | ≥24 | 480-520 |

Typical application scenarios

Wear-resistant steel is widely used in high-wear occasions such as mining, coal transportation, metallurgical processing, concrete equipment, construction machinery, loading and unloading equipment, etc. It is the preferred material for hoppers, chutes, crusher liners, mixing drums, buckets, and other components. In these typical applications, the equipment is exposed to extreme conditions such as high-frequency impact, friction, dus,t and corrosion for a long time, which places extremely high demands on material performance. The use of wear-resistant steel can effectively extend the life of key components, ensure the continuous operation of the production line, and reduce unplanned downtime caused by component wear. Especially in the mining or construction industry, wear-resistant steel has become a core material for improving equipment performance and reliability.

Quality Assurance

The wear-resistant steel plate products we provide strictly follow the high-standard production system at home and abroad, use high-quality raw materials, and introduce advanced quenching and tempering technology to ensure that the products achieve a scientific balance between hardness, toughness, and processing performance. Each batch of steel plates is strictly tested, including Rockwell hardness, metallographic structure, impact test, and dimensional tolerance, to ensure quality consistency and traceability. At the same time, we provide customers with customized cutting, welding, and processing services to meet the personalized needs in different application environments. Choosing us means choosing a stable, reliable, technologically advanced, and considerate wear-resistant steel partner.

Product Inquiry

Relevant Products